DIY Table Saw Push Stick: A simple, yet crucial tool for any woodworker, the push stick is a safety device that can prevent serious injuries. While operating a table saw, it’s easy to get caught up in the excitement of the project, but it’s essential to prioritize safety. This guide will walk you through the importance of using a push stick, different designs, and how to build your own.

From the basic single stick to more elaborate push blocks, there are many designs to choose from. The key is to find a design that works best for your needs and provides a secure grip. You’ll also learn about the essential materials and tools required for building a DIY push stick, along with safety considerations and tips for maintaining your push stick.

Importance of Push Sticks: Diy Table Saw Push Stick

A push stick is an essential safety tool for any woodworker using a table saw. It helps to keep your fingers away from the blade while feeding the wood, minimizing the risk of serious injury.

Safety Benefits of Using a Push Stick

Using a push stick provides several safety benefits, including:

- Keeps fingers away from the blade: The primary function of a push stick is to keep your fingers away from the rotating blade, which is the most dangerous part of the table saw. By using a push stick, you create a safe distance between your fingers and the blade, reducing the risk of accidental contact.

- Provides control over the workpiece: A push stick helps maintain control over the workpiece as it passes through the blade. This is especially important when working with smaller pieces of wood or when making intricate cuts. By keeping the workpiece stable, you reduce the risk of kickback, which can be a dangerous and unpredictable event.

- Reduces the risk of kickback: Kickback occurs when the workpiece binds or catches on the blade, causing it to be thrown back towards the operator. Using a push stick can help prevent kickback by maintaining a steady feed and keeping the workpiece from binding.

- Improves accuracy and consistency: Using a push stick can help improve the accuracy and consistency of your cuts. By keeping the workpiece stable and controlled, you can make cleaner and more precise cuts.

Risks Associated with Not Using a Push Stick

Not using a push stick can expose you to several risks, including:

- Severe finger injuries: The most common and serious injury associated with not using a push stick is a finger amputation or severe laceration. This can happen if your fingers get too close to the blade while feeding the wood.

- Kickback injuries: Kickback can result in serious injuries, including broken bones, cuts, and head injuries. The force of the kickback can throw the workpiece and even the saw blade towards the operator, causing significant damage.

- Burns: The table saw blade can become very hot during use. If your fingers come into contact with the blade, you can suffer severe burns.

Real-World Examples of Accidents

There have been many documented cases of accidents that could have been prevented with the use of a push stick. Some examples include:

- A woodworker lost three fingers while attempting to cut a small piece of wood without using a push stick. The wood got stuck in the blade, causing the woodworker’s hand to be pulled into the saw.

- A carpenter suffered a severe kickback injury when he attempted to cut a piece of wood without using a push stick. The wood kicked back with such force that it struck the carpenter in the chest, causing him to fall and break his ribs.

Materials and Tools

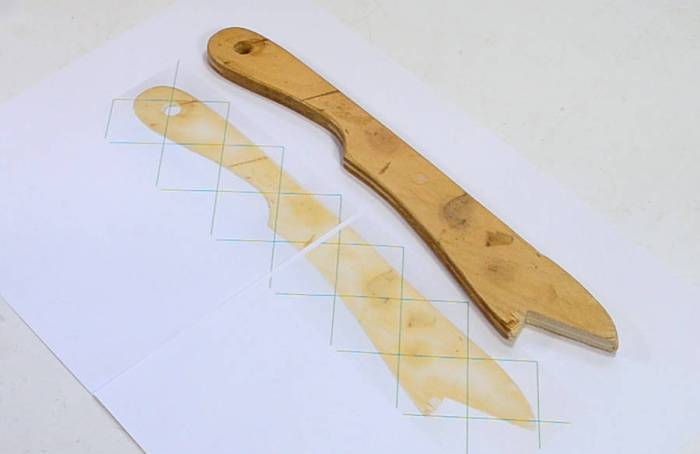

Creating a push stick is a simple DIY project, and the materials you need are readily available. The right materials can make your push stick more durable and functional. Let’s explore the common materials and tools for building a push stick.

Materials

The type of material you choose will depend on your needs and preferences. Here are some popular options:

- Wood: Wood is a popular choice for push sticks due to its availability, affordability, and ease of working with. Hardwoods like maple or oak are strong and durable, while softwoods like pine or cedar are more affordable.

- Advantages: Wood is a readily available and affordable material. It is also relatively easy to work with and can be shaped to fit your needs.

- Disadvantages: Wood can be susceptible to moisture damage and can splinter if not properly finished.

- Plastic: Plastic is a good choice for push sticks because it is durable, water-resistant, and easy to clean. You can use PVC pipe, acrylic sheet, or even a plastic cutting board.

- Advantages: Plastic is durable, water-resistant, and easy to clean.

- Disadvantages: Plastic can be difficult to shape and may not be as strong as wood.

- Metal: Metal is the most durable option for push sticks. You can use aluminum, steel, or even brass. Metal is more difficult to work with than wood or plastic, but it will last longer.

- Advantages: Metal is extremely durable and can withstand heavy use.

- Disadvantages: Metal can be more difficult to work with and may be more expensive than other materials.

Tools

The tools you need to build a push stick will depend on the materials you choose. Here are some essential tools:

- Saw: A saw is essential for cutting the material for your push stick. A hand saw, jigsaw, or table saw can be used depending on the material and the desired shape.

- Drill: A drill is needed to create holes for attaching parts of the push stick or for mounting it to your table saw.

- Screwdriver: A screwdriver is needed to attach the parts of the push stick together.

- Sandpaper: Sandpaper is used to smooth the edges of the push stick and to remove any rough spots.

- Measuring tape: A measuring tape is essential for accurately measuring the materials for your push stick.

- Pencil: A pencil is used to mark the material for cutting and drilling.

- Safety glasses: Always wear safety glasses when working with power tools or sharp objects.

Safety Considerations

While push sticks are a great safety tool, they can also be dangerous if used improperly. It is essential to understand the correct techniques and potential hazards associated with using a push stick.

Proper Grip and Technique

A firm grip on the push stick is crucial for safe operation. When using a push stick, always maintain a firm grip with your dominant hand. This grip should be secure enough to control the workpiece but not so tight that it restricts your ability to maneuver the push stick. Use your non-dominant hand to guide the workpiece and maintain a stable position.

Potential Hazards

Using a push stick incorrectly can lead to various hazards. For instance, if you hold the push stick too close to the blade, you risk getting your hand or fingers caught in the saw. Similarly, if you use a push stick that is too short, you may not have sufficient leverage to control the workpiece, potentially leading to kickback.

Safety Tips for Different Types of Wood, Diy table saw push stick

- Hardwoods: When working with hardwoods, ensure the push stick is robust and has a firm grip. Hardwoods tend to be more difficult to cut and can create more kickback. A longer push stick can provide better leverage and control.

- Softwoods: Softwoods are generally easier to cut, but they can still pose a risk of kickback. Use a push stick that is well-suited for the size and shape of the workpiece. It is also important to ensure that the push stick is smooth and free of any sharp edges.

- Plywood: Plywood can be more challenging to cut due to its layered structure. When using a push stick with plywood, be sure to use a push stick with a wide surface area to help prevent the workpiece from slipping or tilting.

Push Stick Maintenance

A well-maintained push stick is essential for safe and efficient woodworking. It ensures smooth operation, prevents injuries, and extends the lifespan of your push stick.

Cleaning and Maintaining a DIY Push Stick

Regular cleaning is crucial for maintaining the effectiveness and longevity of your push stick. It helps remove sawdust, resin, and other debris that can accumulate during use.

- After each use, wipe down the push stick with a damp cloth to remove any loose sawdust or debris.

- For stubborn stains or resin buildup, use a mild soap and water solution. Avoid harsh chemicals that could damage the wood or finish.

- If your push stick has a finish, apply a light coat of wood oil or wax periodically to protect it from moisture and wear.

Identifying Signs of Wear and Tear

Over time, your push stick may show signs of wear and tear. Recognizing these signs is crucial for determining when repairs or replacement are necessary.

- Cracks or Splits: Cracks or splits in the wood indicate structural weakness and can compromise the push stick’s stability. These should be addressed promptly.

- Loose or Worn Parts: If any parts of your push stick, such as screws or handles, become loose or worn, they should be tightened or replaced to ensure proper functionality.

- Excessive Wear on the Pushing Surface: The pushing surface of your push stick may show signs of wear over time. If it becomes excessively worn, it may not provide sufficient grip on the workpiece, requiring replacement.

Storing Push Sticks Safely and Effectively

Proper storage is essential for protecting your push stick from damage and ensuring it’s readily available for use.

- Store your push stick in a dry and clean location, away from direct sunlight and heat sources.

- Consider using a dedicated storage container or rack to keep your push stick organized and protected.

- If you have multiple push sticks, label them clearly to avoid confusion and ensure you use the appropriate one for the task at hand.

Push Stick Alternatives

While push sticks are highly effective for many table saw tasks, they aren’t always the best option. Other safety devices and techniques can be employed to ensure safe wood feeding.

Alternative Safety Devices

Different tools and techniques can be used to safely feed wood into a table saw.

- Featherboards: Featherboards are adjustable, angled boards with strategically placed fingers or teeth that help guide the wood against the fence. They are particularly effective for preventing kickback when ripping narrow boards.

- Zero-clearance Inserts: These inserts fit into the table saw’s miter slot and reduce the opening between the blade and the table, minimizing the risk of kickback and improving accuracy.

- Push Blocks: Push blocks are similar to push sticks but have a larger, more substantial base that provides greater stability and control. They are ideal for feeding large or heavy pieces of wood.

- Hold-downs: Hold-downs are clamps that secure the wood to the table saw’s surface, preventing it from moving during the cut. They are often used in conjunction with push sticks or other safety devices.

- Outfeed Support: An outfeed support is a table or platform positioned behind the table saw to provide a stable surface for the wood after it has been cut. This reduces the risk of the wood falling or being ejected from the saw.

- Ripping Guides: These specialized tools, often made of metal, can be used to guide the wood during ripping operations, reducing the need for constant manual control and minimizing the risk of kickback.

Effectiveness of Push Sticks Compared to Other Methods

The effectiveness of different safety devices varies depending on the specific task and the type of wood being cut.

- Push Sticks are excellent for guiding smaller pieces of wood, especially during ripping operations. They are versatile and can be adapted for different cutting angles.

- Featherboards are particularly effective for preventing kickback when ripping narrow boards, as they provide a more consistent guiding force.

- Zero-clearance Inserts improve accuracy and reduce the risk of kickback by minimizing the gap between the blade and the table.

- Push Blocks are ideal for feeding large or heavy pieces of wood, providing greater stability and control.

- Hold-downs are essential for securing the wood to the table saw’s surface, preventing it from moving during the cut.

- Outfeed Support provides a stable surface for the wood after it has been cut, reducing the risk of the wood falling or being ejected from the saw.

- Ripping Guides are designed for specific ripping operations, offering greater precision and safety.

Situations Where Push Sticks Might Not Be the Best Option

While push sticks are versatile, they may not be the best choice for every situation.

- Cutting Large or Heavy Pieces of Wood: In these cases, push blocks or hold-downs provide greater stability and control.

- Ripping Narrow Boards: Featherboards are more effective at preventing kickback when ripping narrow boards.

- Cutting Thick Stock: For thick materials, push blocks or hold-downs might be necessary to provide adequate support.

- Operations Requiring Precision: For tasks requiring precise cuts, ripping guides or zero-clearance inserts may be more suitable.

Investing time in creating a DIY table saw push stick can be a worthwhile endeavor. Not only will it enhance your woodworking experience, but it will also give you peace of mind knowing that you are working safely. Remember, a well-made push stick is an essential tool for any woodworker who wants to prevent accidents and enjoy their craft to the fullest.

A DIY table saw push stick is a must-have for any woodworker, providing safety and control during cutting. Similar to a DIY project like patio pavers diy , where you create something beautiful and functional, a well-crafted push stick adds value to your woodworking endeavors. The push stick’s simple design, like a patio paver’s, can be adapted to suit your needs, ensuring a smooth and secure operation.