DIY pulley systems offer a fascinating blend of simplicity and power, allowing you to harness the principles of mechanical advantage to lift heavy objects, move furniture, and even create innovative machines. Whether you’re tackling a home improvement project, exploring the world of engineering, or simply seeking a creative challenge, building a DIY pulley system can be an enriching and rewarding experience.

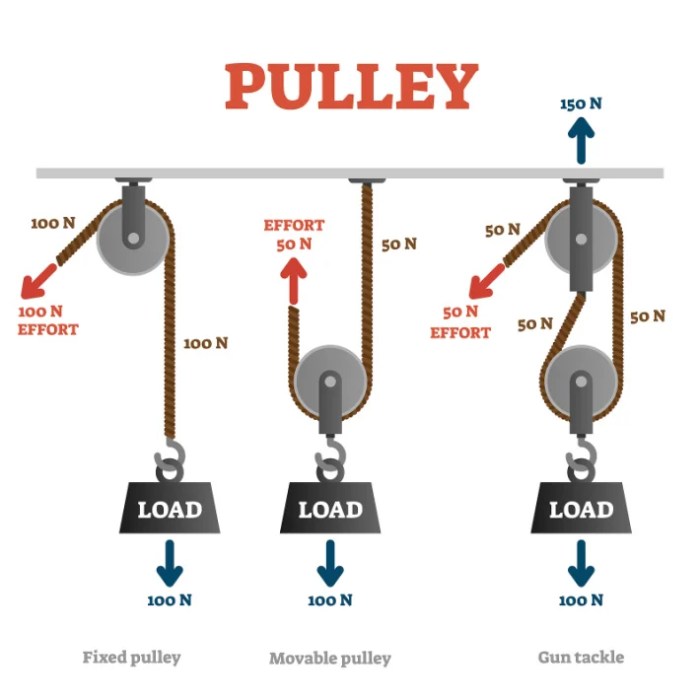

Understanding the fundamental principles of pulley systems is essential for successful construction and safe operation. Pulley systems work by redirecting force, allowing you to lift objects with less effort. This is achieved through the use of ropes and pulleys, which act as simple machines to multiply your force. The type of pulley system you choose will depend on your specific needs, such as the weight you need to lift, the available space, and the desired mechanical advantage.

Designing a DIY Pulley System

A pulley system is a simple but powerful mechanism that uses ropes and wheels to amplify force and lift heavy objects. It’s a common tool used in various applications, from construction and industrial settings to everyday tasks like lifting furniture or hanging heavy decorations. Building your own pulley system can be a rewarding project, allowing you to customize it for specific needs and save money compared to buying a pre-made system.

Designing a Pulley System for a Specific Task

The first step in designing a DIY pulley system is to determine the task you want to accomplish. Consider the weight of the object you need to lift, the distance you need to lift it, and the available space. Once you have a clear idea of the task, you can start designing your pulley system.

Calculating Required Rope Length and Pulley Configuration

The required rope length and pulley configuration are crucial for the proper functioning of a pulley system. These factors directly impact the mechanical advantage, which is the ratio of the output force to the input force. A higher mechanical advantage means you can lift heavier objects with less effort.

The mechanical advantage of a pulley system is equal to the number of supporting ropes.

For example, a simple pulley system with one pulley and two supporting ropes has a mechanical advantage of 2. This means you can lift twice the weight with the same force.

To calculate the required rope length, you need to consider the distance you need to lift the object and the number of supporting ropes in your pulley system. The total rope length should be twice the lifting distance plus the length needed for securing the rope to the pulleys and the load.

Tools and Equipment for Building a DIY Pulley System

Building a DIY pulley system requires specific tools and equipment to ensure safety and functionality. Here’s a list of essential tools and safety gear:

- Pulley wheels: Choose sturdy and durable pulley wheels with a load capacity that exceeds the weight you’re lifting. The number of pulleys will depend on the desired mechanical advantage.

- Rope: Select a strong and durable rope with a breaking strength that exceeds the load you’re lifting. The rope should be long enough to accommodate the lifting distance and the pulley configuration.

- Hooks or shackles: Use hooks or shackles to secure the rope to the pulleys and the load. Ensure they have a safe working load limit (SWL) that exceeds the load you’re lifting.

- Screws, nuts, and bolts: Use screws, nuts, and bolts to assemble the pulley system and attach it to a secure structure.

- Measuring tape: Use a measuring tape to determine the required rope length and the dimensions of your pulley system.

- Safety gear: Always wear safety gear when working with heavy objects and pulley systems. This includes safety glasses, gloves, and a helmet.

Safety Considerations for DIY Pulley Systems

DIY pulley systems can be incredibly useful for lifting heavy objects, but they also present inherent risks if not built and used properly. It’s crucial to prioritize safety when working with these systems to prevent accidents and injuries.

Safety Precautions for DIY Pulley Systems

Safety precautions are essential for minimizing the risk of accidents and injuries while working with DIY pulley systems. These precautions involve using appropriate safety gear, employing proper lifting techniques, and maintaining the system regularly.

- Wear appropriate safety gear: Always wear sturdy work gloves to protect your hands from rope burns and potential snags. Safety glasses or goggles are also important to shield your eyes from debris or falling objects. In situations involving significant weight, consider wearing a hard hat to protect your head from potential falling objects. Additionally, a safety harness can be used to secure yourself to the system, particularly when working at heights.

- Use proper lifting techniques: When lifting heavy objects with a pulley system, it’s crucial to maintain a firm grip on the rope and lift with your legs, not your back. Avoid twisting your body while lifting, and ensure you have a stable footing to prevent falls. If lifting alone, use a mechanical advantage system to reduce the effort required. Always lift with a spotter or helper for safety, especially when dealing with heavier loads.

- Inspect the system regularly: Before each use, thoroughly inspect the rope, pulleys, and other components for signs of wear, damage, or corrosion. Replace any damaged or worn parts immediately to prevent potential failures. This includes checking the rope for fraying, the pulleys for cracks or broken bearings, and the anchor points for secure attachment. Regular maintenance and inspection are vital for ensuring the continued safety and functionality of the pulley system.

Potential Hazards Associated with DIY Pulley Systems

DIY pulley systems, while useful, can pose significant risks if not constructed and used properly. Recognizing potential hazards is essential for mitigating risks and ensuring safety.

- Rope failure: Overloading the rope beyond its rated capacity can lead to failure, potentially causing the load to fall. Always select a rope with a safety factor of at least 5, meaning it can handle at least five times the weight of the load being lifted. Inspect the rope regularly for signs of wear, fraying, or damage, and replace it if necessary.

- Pulley malfunction: Pulley malfunctions can occur due to worn bearings, broken sheave axles, or improper installation. These malfunctions can cause the rope to bind, slip, or even detach, leading to the load falling. Always use high-quality pulleys designed for the load being lifted, and inspect them regularly for any signs of damage or wear.

- Improper installation: Improper installation of the pulley system can lead to instability, resulting in the system collapsing and the load falling. Ensure that the anchor points are secure and can withstand the load being lifted. Use appropriate hardware and fastenings for the chosen anchor points, and double-check all connections for stability.

Guidelines for Maintaining and Inspecting DIY Pulley Systems

Regular maintenance and inspection of DIY pulley systems are crucial for ensuring their continued safety and functionality. These guidelines help to identify potential problems early and prevent accidents.

- Regular inspection: Inspect the rope, pulleys, and anchor points before each use for signs of wear, damage, or corrosion. Replace any damaged or worn components immediately. This includes checking the rope for fraying, the pulleys for cracks or broken bearings, and the anchor points for secure attachment.

- Lubrication: Lubricate the pulleys regularly with a suitable lubricant to reduce friction and prevent wear. Avoid using excessive lubricant, as it can attract dirt and grime.

- Storage: Store the pulley system in a dry, clean place when not in use to prevent corrosion and damage. Avoid storing the rope in direct sunlight or extreme temperatures, as this can weaken the fibers.

Pulley Systems in History and Culture

The pulley system, a simple yet ingenious invention, has played a pivotal role in human civilization since ancient times. Its ability to multiply force and ease the lifting of heavy objects has revolutionized industries, construction, and transportation, leaving an enduring mark on our history and culture.

Ancient Origins and Early Applications

The earliest evidence of pulley systems dates back to ancient Mesopotamia, around 3000 BC. Simple rope-and-wheel systems were used to lift water from wells and move heavy stones during construction. The Egyptians, known for their monumental pyramids, employed pulley systems to raise massive blocks of stone, demonstrating the early understanding of this fundamental principle. The Greeks and Romans further developed pulley systems, using them in various applications, including cranes for construction and shipbuilding. The concept of a pulley system is based on the fundamental principle of mechanical advantage, which allows a smaller force to lift a heavier load by utilizing a system of ropes and wheels. This principle has been utilized for centuries, and its influence can be seen in various aspects of our modern world.

Pulley Systems in Construction and Engineering

Pulley systems have been indispensable in construction and engineering projects throughout history. The construction of ancient structures like the pyramids, aqueducts, and temples relied heavily on pulley systems to lift and move heavy materials. During the Renaissance, the development of more sophisticated pulley systems enabled the construction of grand cathedrals and palaces, showcasing the increasing complexity and efficiency of these devices. In modern times, pulley systems are used in cranes, elevators, and other heavy-duty machinery, enabling the construction of skyscrapers and other complex structures.

Pulley Systems in Transportation and Industry, Diy pulley system

Pulley systems have also played a crucial role in transportation and industry. The development of sailing ships relied heavily on pulley systems for raising and lowering sails, allowing for more efficient navigation and trade. In the Industrial Revolution, pulley systems powered by steam engines were used in factories for lifting and moving materials, contributing to the mass production of goods. Today, pulley systems are essential in various industries, from manufacturing and logistics to mining and oil drilling. Their versatility and efficiency make them indispensable tools for modern industrial processes.

Pulley Systems in Everyday Life

Pulley systems are not only found in large-scale engineering projects but also in everyday life. Simple pulley systems are used in window blinds, clotheslines, and garage doors, making it easier to lift and lower objects. Even the simple act of pulling a bucket from a well utilizes a basic pulley system. These everyday examples highlight the pervasive influence of pulley systems in our daily lives.

Cultural Significance of Pulley Systems

Pulley systems have also been featured in art, literature, and mythology, reflecting their cultural significance. In ancient Greek mythology, the god Heracles used a pulley system to lift the Nemean lion, highlighting the power and ingenuity associated with this simple invention. Pulley systems have also been depicted in paintings and sculptures, capturing their importance in human endeavors. The cultural significance of pulley systems reflects their enduring impact on human civilization.

DIY pulley systems are a testament to the power of simple machines and the ingenuity of human design. By understanding the basic principles, carefully selecting materials, and following safe practices, you can create a pulley system that meets your specific needs and unlocks a world of possibilities. From tackling everyday tasks to embarking on ambitious projects, the versatility of DIY pulley systems makes them a valuable tool for anyone with a curious mind and a desire to harness the power of mechanics.

DIY pulley systems are great for lifting heavy objects, and they can be surprisingly easy to build. But if you’re looking for a more efficient way to cool your home, you might want to consider installing a mrcool diy mini split. These systems are designed to be easy to install, and they can help you save money on your energy bills.

Of course, if you’re still interested in DIY projects, you can always build a pulley system to help you lift the heavy components of your new mini split!